In today’s fast-paced world, the logistics industry is constantly seeking innovative solutions to improve efficiency and productivity. One cutting-edge technology that has gained significant attention is robot logistics. This article will explore how robots are transforming the way goods are transported and stored, making logistics operations more streamlined and cost-effective.

The Rise of Robot Logistics

Robot logistics refers to the use of autonomous robots in various aspects of supply chain management, including material handling, inventory management, and order fulfillment. These robots are equipped with advanced sensors and artificial intelligence algorithms that enable them to navigate through warehouses or distribution centers without human intervention.

By utilizing robot logistics systems, companies can significantly reduce labor costs while increasing operational efficiency. These robots can work 24/7 without breaks or fatigue, ensuring continuous workflow throughout the day. They can also perform repetitive tasks with precision and accuracy, minimizing errors in order processing.

Youibot: A Game-Changer in Robot Logistics

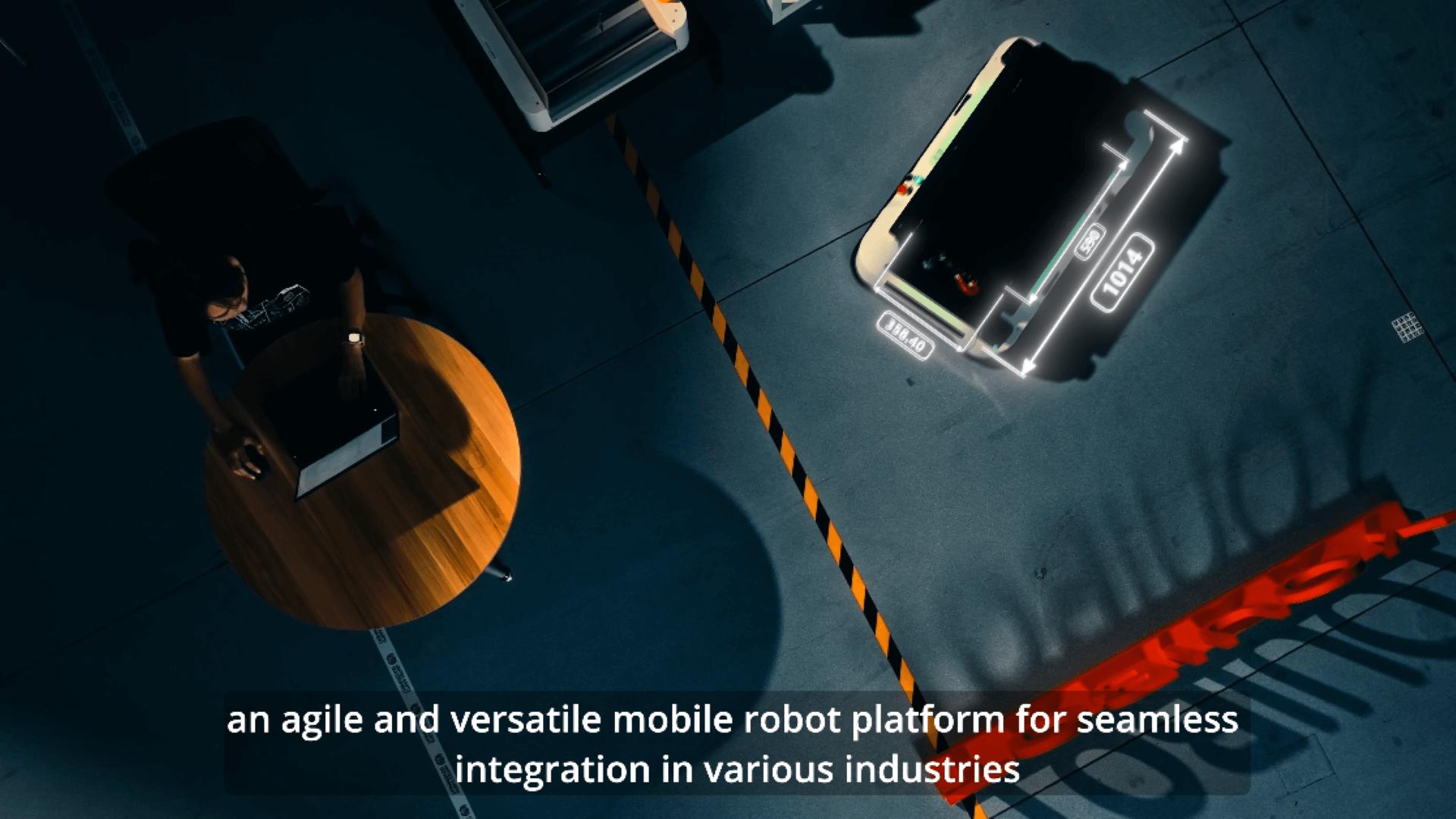

One notable player in the field of robot logistics is Youibot – a leading robotics company specializing in autonomous mobile robots (AMRs). Their AMR technology combines state-of-the-art hardware with intelligent software algorithms to create highly efficient robotic solutions for warehouse automation.

Youibot’s AMRs are designed to seamlessly integrate into existing warehouse infrastructure. Equipped with advanced perception systems and real-time mapping capabilities, these robots can autonomously navigate complex environments while avoiding obstacles along their path.

The versatility of Youibot’s AMRs allows them to handle a wide range of tasks within a warehouse setting. From picking up items from shelves to transporting heavy loads across long distances, these robots offer unparalleled flexibility and adaptability for diverse logistical needs.

The Advantages of AMR Technology

amr technology offers several advantages over traditional manual labor and other automated systems. Firstly, these robots can be easily deployed and reconfigured to meet changing operational requirements. This flexibility allows companies to quickly adapt to market demands without significant downtime or costly infrastructure changes.

Furthermore, AMRs are equipped with advanced safety features that ensure the well-being of both human workers and the robots themselves. They can detect obstacles in real-time and adjust their path accordingly, minimizing the risk of accidents or collisions.

In terms of efficiency, AMRs excel at optimizing warehouse operations. With their ability to communicate with each other and coordinate tasks, they can streamline order fulfillment processes by reducing travel time between different areas within a facility.

The Future of Robot Logistics

The integration of robot logistics into supply chain management is expected to continue growing rapidly in the coming years. As technology advances further, we can anticipate even more sophisticated robots capable of handling complex tasks such as item sorting or quality control.

With increased automation and improved efficiency brought about by robot logistics systems like Youibot’s AMRs, businesses will be able to enhance customer satisfaction through faster delivery times and reduced errors in order processing. The future looks promising for this cutting-edge technology as it revolutionizes the way goods are handled throughout the entire logistics industry.